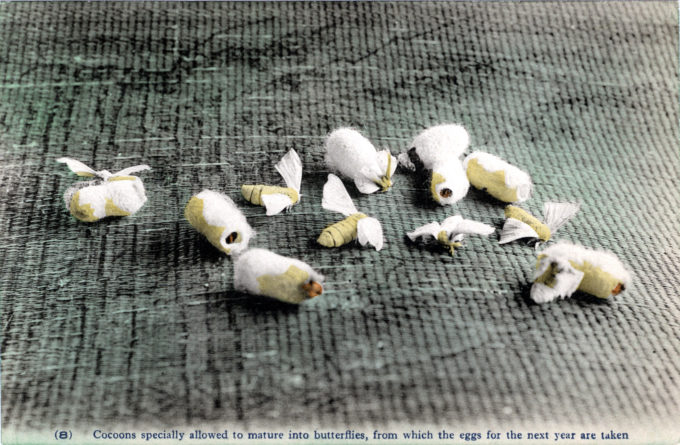

“Cocoons specially allowed to mature into butterflies, from which the eggs for the next year are taken,” c. 1920.

See also:

Silk Conditioning House, Yokohama, c. 1935

“Triggered by the arrival of Admiral Perry from the United States, Japan’s 215-year isolation period came to an end in 1859. After that, Japanese silk-reeling industry changed dramatically, and its silkworm eggs and raw silk started to be sold significantly as global products.

“The end of isolation, by the conclusion of a treaty of emphasizing amity and commerce with Western countries, also sparked the dawn of Japan’s export industry. More and more people gathered in the treaty ports, including Yokohama, from around Japan, borrowing premises allocated by the feudal government for business, dreaming of making a fortune. It was thought to be just like the gold rush in the United States.

“Jube Nakaiya was the first to venture into Yokohama from Gunma Prefecture. He opened a shop called Akagane Goten (copper palace) and acquired immense wealth as a raw silk trader. Zentaro Shimomura, who became the first mayor of Maebashi City, also in Gunma Prefecture, also worked hard to sell and export his area’s raw silk. The name of ‘Maebashi’ became well known to London, the capital of the United Kingdom, and Lyon, France. It is said that the best quality raw silk in Japan at this time was called ‘Maibashi’ (or, as it sounded to a Western ear, ‘Mybash’).

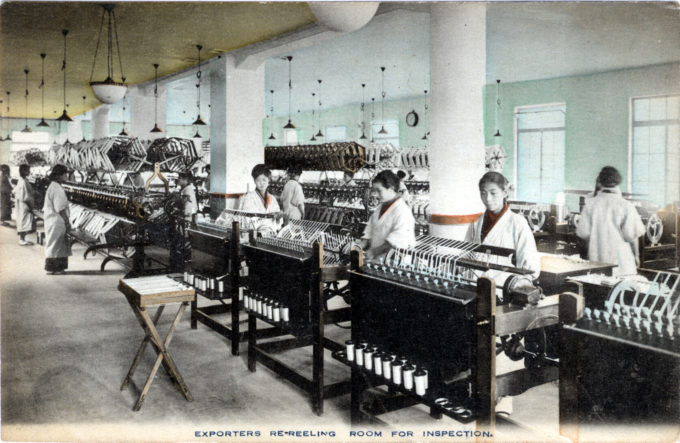

“As raw silk became a prominent export, the silk-reeling industry developed remarkably. An improved manual silk reeling method called ‘Kairyo Zaguri’ was developed in Gunma Prefecture. Through this method, raw silk reeled by each farmer was sorted to standardize, and re-reeled onto bigger reel. Among the first unions organized in Japan were formed by silk-raising farmers who, individually, did not have much capital to make manufacturing improvements. Those organizations improved the quality of silk yarns, and dramatically expanded silk production volume.”

– Tomioka Silk Mill and Related Sites, World Heritage Sites, Gumma Prefectural Government, 2014

- “The silkworms taking their third sleep,” c. 1920.

- “After taking their fourth sleep, the worms are now matured sufficiently to permit of selection,” c. 1920.

- “Reeling the thread out of cocoons”, c. 1910.

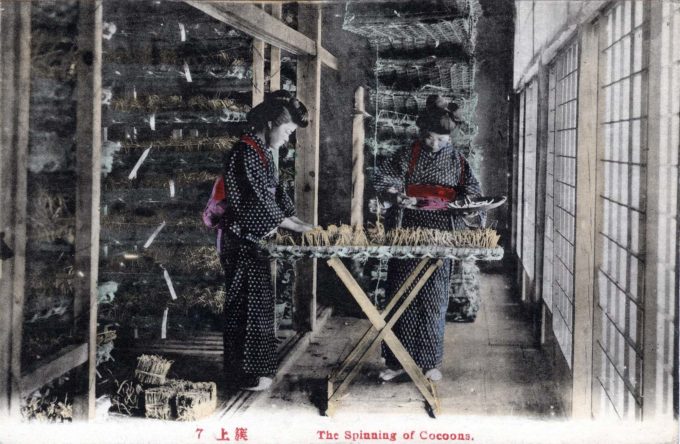

- “The spinning of cocoons”, c. 1910.

“‘Sericulture’, or silk farming, is the rearing of silkworms for the production of silk. According to Confucian text, the discovery of silk production dates to about 2700 BC.

“Silkworm larvae are fed with mulberry leaves, and, after the fourth moult, climb a twig placed near them and spin their silken cocoons. This process is achieved by the worm through a dense fluid secreted from its structural glands, resulting in the fiber of the cocoon.

“The silk is a continuous filament comprising fibroin protein, secreted from two salivary glands in the head of each larva, and a gum called sericin, which cements the filaments. The sericin is removed by placing the cocoons in hot water, which frees the silk filaments and readies them for reeling. This is known as the degumming process. The immersion in hot water also kills the silkworm pupae.

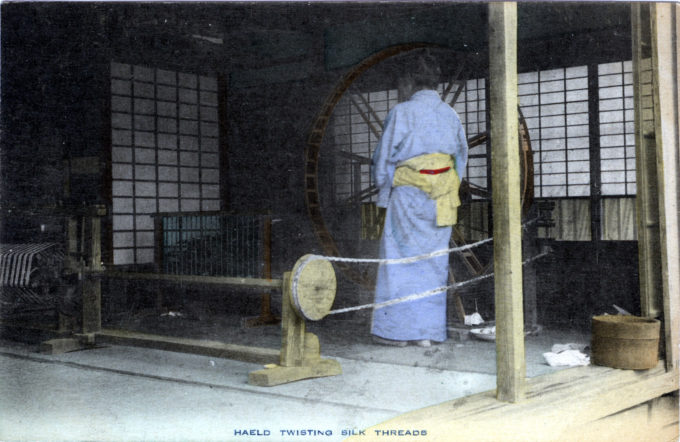

“Single filaments are combined to form thread, which is drawn under tension through several guides and wound onto reels. The threads may be plied to form yarn. After drying, the raw silk is packed according to quality.”

– Wikipedia